This unit machine is special design for packaging liquid& sauces product into plastic bag .The machine have the function of automatic bag forming, Liquid product measuring and filling .With optional function of exhausting the air inside the bag and then sealing the bag .The machine also have color ribbon for date printer for coding of expiry date and production date.Widely use for packaging different liquid and paste product.

1, ZL520 vertical bag forming filling sealing Packaging machine

The whole machine made by Stainless Steel 304. This machine equipped with bag-making, cutting, code printing, etc. Siemens PLC and Touch Screen,Panasonic servo motor, Japanese Photo Sensor , Korean Air valve, etc. .The film pulling system adopted servo motor driving making speed faster.

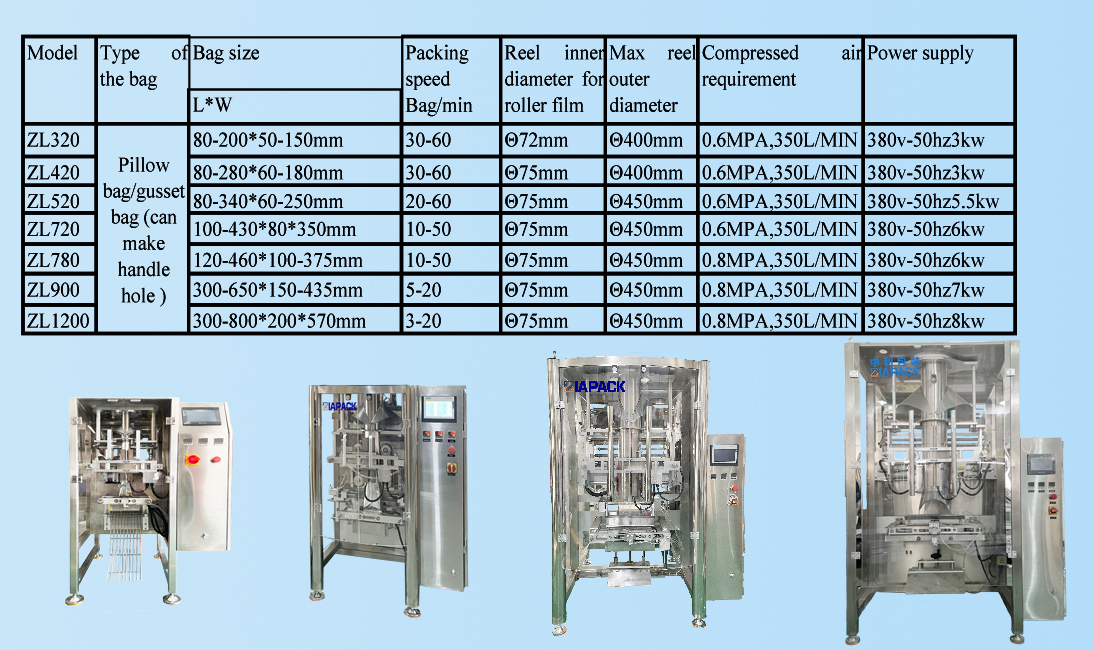

Teknikal Parameter:

Weighing Range: 1000-2000g

Packaging Speed: 20-40 bags/min

Bag size: (80-360)*(100-250) mm (L*W)

Kinakailangan ng naka-compress na hangin: 0.6Mpa 0.65m³/min

Reel outer diameter: 400mm

Core panloob na diameter: 75mm

Machine weight: 800kg

Power source: 5.5kW 380V±10% 50Hz

Pangunahing Katangian at Katangian:

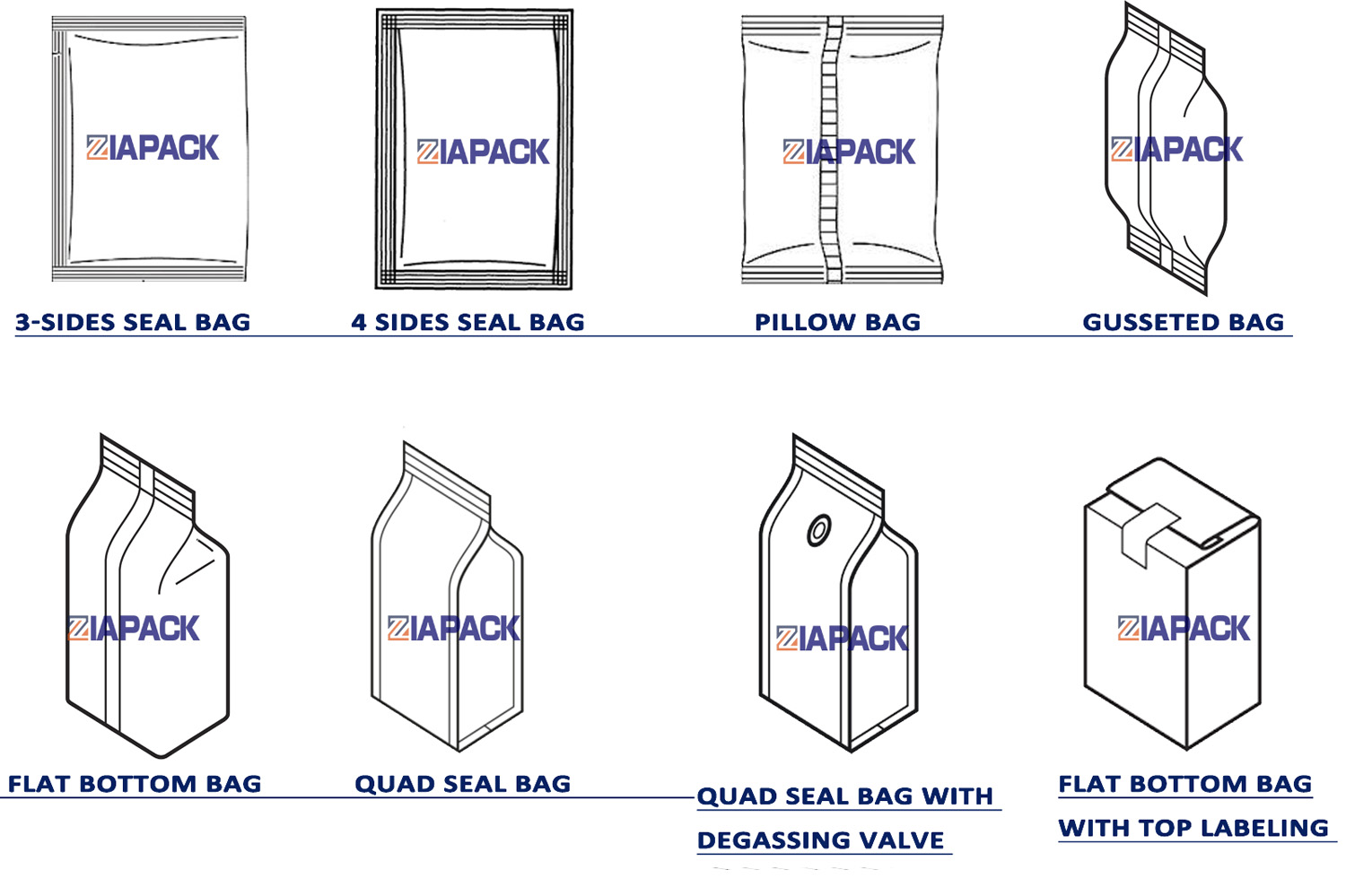

A wide range of pouches: Pillow and Gusset pouches.

High speed: 20-50 bags/min

Madaling patakbuhin: PLC controller at color touch-screen, fault indication sa touch screen.

Madaling ayusin: lamang tungkol sa 10 minuto upang baguhin ang iba't ibang mga pouches.

Pagkontrol ng dalas: maaaring iakma ang bilis ng conversion ng dalas sa hanay.

Mataas na Automation: hindi pinuno ng tao sa pagtimbang at packing proseso, awtomatikong makina alarma kapag kabiguan.

Kaligtasan at Kalinisan:

Walang pelikula, mag-aalarma ang makina.

Ang alarma ng makina at itigil kapag ang hindi sapat na presyon ng hangin.

Mga tagapangalaga ng kaligtasan na may kaligtasan-switch, alarma machine at itigil kapag ang mga kaligtasan guards ay binuksan.

Kalinisan konstruksiyon, ang mga bahagi ng produkto contact ay pinagtibay sus304 hindi kinakalawang na asero.

Bag type

2,ZLB100 Piston pump with hopper

Mga Tampok

Standard with Airtac Piston.

All piston filler made from S/S 304 grade stainless steel and aluminum conforms to GMP.

Suit for Viscous Liquid Model with stainless steel product hopper

Operated by foot pedal switcher or matching with full automatic packaging machine

With Anti-leaking system

Quick release nozzle and feed pipe

Technical parameter :

Filling range: 50-500 ML

Power supply: 220V 50HZ

Total power Power: 1650W

Heating power:1500W

Temperature range:20-90℃

Weight: 55kg

Hopper capacity: 30L

Air pressure: 0.4-0.6mpa

Working mode: need to be equipped with a power supply and air compressor

Machine material: case 201 stainless steel, material contact part is 304 stainless steel

Pagpuno katumpakan: ± 1%

Filling efficiency: 0-25 bottles /H

Packing size:96*36*36cm (machine) + 60*54*81cm(hopper)